Electrical Engineers and Workplace Safety

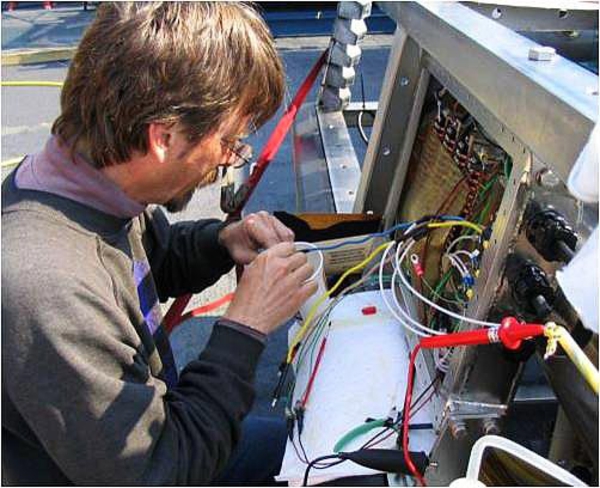

Electrical engineers commonly work in hazardous conditions, requiring both the proper equipment and techniques to avoid the potential for serious injury or death. Contrary to most popular views, this does not simply include the risk of electrocution, but burns, exposure to hazardous materials and the potential for falls when working on electrical systems.

Hazards of Electrical Engineering

Electrical engineering is a profession whose workers face a variety of hazards. Failing to adequately prepare for them can lead to the severe injury or death, for the engineer and coworkers alike. Among the most common hazards are the following:

• Working with active equipment and power lines.

When working with electrical equipment, receiving shocks can be the result of working on equipment or lines that are currently “live” or inadvertent contact with operating equipment. This is especially true for engineers working on power lines, where he or she may be operating in close proximity with lines that are still carrying a current.

• Exposure to hazardous chemicals.

In many cases, an electrical engineer will be working with industrial equipment that may expose him or her to dangerous chemicals. In the aftermath of a fire or short, vaporized insulation or components may have resulted in concentrations of dangerous gases, which can pose a health risk, especially in enclosed spaces.

• Working on scaffolds or other elevated areas.

Many electrical repair jobs require the engineer to perform work while suspended from a crane or after climbing a scaffold to reach the job site. In addition to the potential for falls, the equipment used to climb and secure the engineer may pose a risk of coming into contact with active electrical lines or equipment, adding to the danger of electrocution.

• Burns and Electrical Fire Danger

An engineer who is repairing equipment or lines may find himself or herself faced with an electrical fire. These fires demand immediate action, both to fight the fire and to successfully shut down the power to the malfunctioning system in order to reduce the danger to the engineer and any fire fighting personnel.

Ensuring the Safety of the Engineer

Fortunately, an effectively trained and cautious engineer can ensure his or her safety by following proper safety guidelines, using the proper equipment, and avoiding risky situations. By doing this, the risk of injury or death on the part of the engineer can be drastically reduced.

Maintaining Tools, Harnesses and Other Equipment

All engineers should ensure that their equipment is properly maintained at all times. Whether it is a voltage tester or the safety harnesses used when working on power transmission towers, it is the engineer’s responsibility to verify that they are in working condition. Furthermore, the engineer must be fully trained on all equipment that he or she will be using in order to make proper and safe use of the equipment.

Avoiding electrical shocks

As one of the most common dangers facing the electrical engineer, it is vital that the engineer ensure that all equipment and lines he or she may be working on have been shut down. This not only includes checking the equipment before working, but using voltage testers to ensure that equipment and power lines alike have been shut down before directly touching them. Furthermore, equipment should be physically disconnected from the power source. If that is not possible, the switches must be clearly tagged and secured to avoid the accidental restoration of power.

In addition, the engineer must remain aware or other power lines or equipment that may not be shut down. By doing so, the worker can avoid the risk of electrocution from inadvertently touching them, with a tool or other item.

Maintaining Communication with Coworkers

Especially in large companies, electrical engineers may be working with a number of coworkers. In this case, it is vital that all personnel understand their duties and how they may impact the electrical engineer. This is especially important when working in an active site where other work is ongoing, such as a production line or warehouse. Equipment under repair should be clearly tagged with lockout/tagout notifications and all workers and visitors made aware of the importance of remaining away from active work areas.

Creating a Safety Centered Work Culture

Maintaining a safe working environment for the electrical engineer requires that the engineer and his or her coworkers maintain a culture of safe work practices. Whether it is in ensuring the equipment is well maintained and all workers are trained in its operation, or keeping all employees clearly informed about any ongoing work, the engineer must never fall to the temptation to skimp on his or her safety precautions. By keeping safety procedures in mind, electrical engineers can avoid the potential for a tragic and avoidable accident.

Nisha is freelance writer currently helping to represent APL Clothing online. APL provide specialised clothing at exceptional prices from workwear, corporate wear, PPE and just about anything else you can think of.